Material behavior under environmental stress explains many thickness discrepancies better than deliberate deception. Responsible WPC Flooring Supplier partners understand that composite materials naturally expand and contract with humidity cycles. During ocean transit, high-moisture environments cause microscopic swelling, while warehouse storage in arid regions triggers contraction. These reversible dimensional changes create temporary measurement variations that resolve after proper acclimatization in installation environments.

Advanced manufacturing addresses this through material science innovation. Leading facilities engineer proprietary polymer formulations with balanced hygroscopic properties and optimized fiber orientation. This creates internal stabilization grids that resist permanent compression during pallet stacking. The most reputable WPC Flooring Supplier operations implement extended conditioning protocols where products stabilize in climate-controlled environments before shipment, ensuring dimensional consistency upon delivery.

Verification methodology remains equally crucial. Professional installers measure thickness after mandatory acclimation using calibrated digital micrometers at multiple board locations. Measurements taken prematurely or with improper tools capture transient states rather than true specifications. Ethical WPC Flooring Supplier leaders provide detailed acclimation guidelines and loaner measurement kits, transforming claims into verifiable realities.

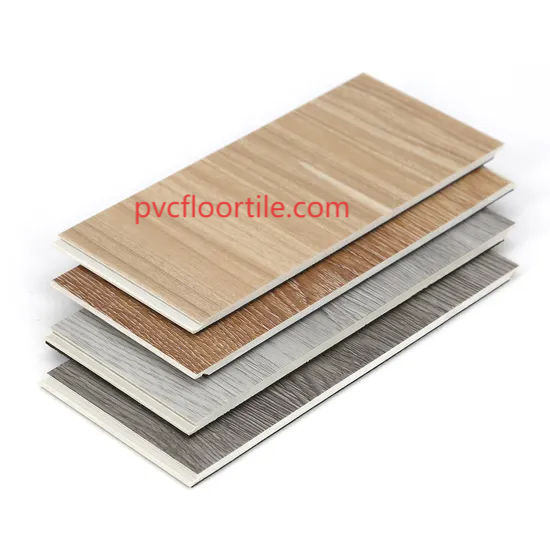

Pvcfloortile's Stability Assurance:

At Pvcfloortile, we engineer equilibrium. Our ClimateLock formulations undergo 90-day conditioning for transit-resistant dimensional stability. Partner with us for flooring where specifications remain unwavering from factory to installation.Click https://www.pvcfloortile.com/product/ to reading more information.